- Home

- > Projects

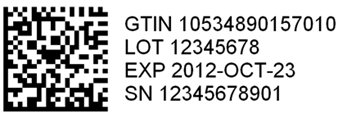

Packaging Line Solution to meet FDA Serilization Mandate

This international pharmaceutical company implemented serialization on multiple packaging lines. This enabled the application of unique and verifiable product identifiers to individual boxes, cases and pallets of drug products.

Gelatin Plant Maximizes Production, Minimizes Costs

The gelatin plant operates 24/7. Automation of manual processes resulted in a gain of two hours of production time per day, or almost 10%, over previous benchmarks. This translates into 1 ½ months of gained production time per year. An independent University of Iowa Study documented water savings alone of over $400,000 per year.

Data Acquisition System Generates 100,000 Reports a Year

Temperature and pressure data from plants in eight states is collected and stored per equipment cycle.

The system architecture is fault-tolerant, delivering robust reliability. Plant personnel can access scheduled reports, generate on-demand reports and make SQL queries.The intranet reporting website can be accessed using any web browser

Virtualization Replaces 37 Servers

GSC turned a batch server hardware failure that threatened to stop production into an opportunity to dramatically improve IT services plantwide.

Server virtualization replaced 37 servers, supported by a cluster of three high-end servers with high availability and no single point of failure